Speaking of diesel fuel, a good place to begin is probably the fact that it is one of the most widespread motor fuels for various vehicles, both land-based (automobiles, tractors, locomotives, tugs) and maritime. Diesel fuel production takes up to 30% of total crude oil produced in the world.

Diesel fuel powers internal combustion engines, sensitive to various contaminants, just as any fuel system. Therefore diesel fuels must comply with certain regulations.

The higher the quality of the fuel, the better the engine operates. Engine’s efficiency is reached due to the anticorrosion properties of diesel fuels. Since these fuels are well purified from contamination which could cause metal corrosion, such contaminants are not a factor. Corrosive activity of fuels is more due to the presence of alkali and mineral acids, water, organic acids and sulfur compounds.

The worldwide environmental deterioration forces many countries to tighten environmental requirements to fuels. Due to the need for reliable and efficient operation of modern vehicles, there are strict requirements to the composition and properties of diesel fuel. Most importantly, these regulations concern the harmful emissions into the environment.

Such emissions include sulfur and ash, as well as polycyclic hydrocarbons. Sulfur was mentioned first for a reason. Sulfur and its compounds are one of the most environmentally hazardous components of diesel fuel.

Publications concerning fuel often use the word sulfur meaning its various compounds: disulfides, sulfides, mercaptan sulfur, thiophane and thiophene.

The hazard of sulfur to internal combustion engines is not only in corrosion, but also the formation of engine sludge. It forms due to combustion of sulfur compounds and can cover the engine with solid and dense film. This is obviously harmful to fuel system. If the need to clean the engine is neglected, the engine fails. Sludge may also contaminate oil. Due to the direct contact with engine parts, the parts wear down, piston rings being the most vulnerable.

In such conditions, the manufacturer of diesel fuel must solve the traditional problem of most industries and productions: how to supply fuel of high quality, compliant with all environmental regulations with minimum costs.

One can find many publications on the web dealing with “cheap diesel polishing”, but not many comprehensively describe methods of quality improvement and polishing of diesel fuel, touching instead on more specific issues. Let us take a broader view of the problem.

Special additives are used for improvement of fuel quality. They are used if the content of sulfur in the fuel is too low. We have spoken of the harmful effects of sulfur, however, if the amount of this substance is insufficient, the fuel’s lubrication properties suffer. This is when additives come into play.

Since the amount of diesel fuel consumed grows annually, the assortment of additives also increases.

The most popular today are the anti-gel, cetane-improving, anti-wear and PPD additives.

Anti-gel additives improve quality of diesel fuel. These additives eliminate crystallization of paraffin in lower temperatures. Without this additives, fuel may become cloudy. This additives serves two purposes: removes water and improves solidification point of fuel. Fuel must be heated before adding anti-gel additives.

The purpose of anti-wear additives is self-explanatory. They are required to improve the fuel’s lubricating properties. They form a protective film on contact with a metal surface.

Cetane number is an indication of the fuel’s combustion ability. Certain additives improve that characteristic. High cetane number improves the fuel’s startability, which is important during cold start of the engine. This type of additives also helps to reduce the amount of harmful emissions in the exhaust.

PPD additives allow summer fuel to be used in winter. The use of PPD also improves the fuel’s lubrication properties, which in many respects influences the lifetime of the fuel system and its components.

There are several chemical and physical methods of sulfur removal.

Sulfuric acid processing involves mixing the fuel with a small amount of 90-93% sulfuric acid. The process runs at normal temperature.

The process results in two substances: purified product and acidic sludge, containing the undesired waste. In general sulfuric acid treatment requires a lot of reagents and is quite cumbersome. Acidic sludge can then be used for production of sulfuric acid.

The drawbacks of the sulfuric acid treatment cause transition to better methods: extraction and hydrotreatment. In future, the acidic treatment may be used for production of white oil, since the large consumption of reagents is not profitable for companies.

Adsorption processing involves bringing the oil product in contact with adsorbents, e.g. silica gels or bleaching clays. They absorb resins and nitric compounds which should be removed from petrochemical products.

Bleaching clay is a natural material with highly pronounced absorption ability. They can decolorize various substances. Until recently, the drawback of this method was incomplete adsorbent regeneration.

Selective polishing methods involve various solvents (nitrobenzene, liquid sulfur dioxide, furfurol, dichorene ethyl ester), which selectively dissolve the harmful substances in an oil product. The main drawback of this method is its inability to restore solvent and its loss. Selective polishing is not widely used for diesel fuel, this method being reserved mostly for oil purification.

Hydrotreatment is used for production of low-sulfur diesel from high-sulfur oil. In the process of hydrotreatment, organic sulfur, oxygen and nitrogen compounds are destroyed. The drawbacks of this method are the high temperature (around 380-420ºC) and pressure (up to 4 MPa), and equipment complexity.

Membrane purification allow to remove sulfides, thiophene, disulfines, mercaptans etc from diesel fuel.

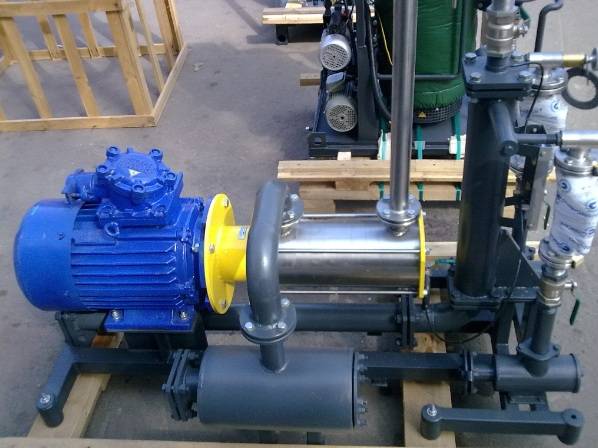

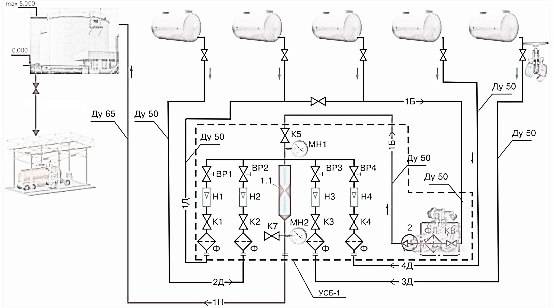

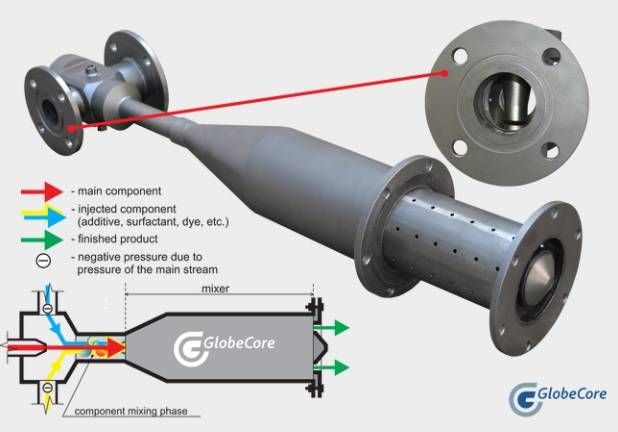

The above are the primary methods of diesel fuel polishing. The selection of a method depends on initial fuel contamination and the required degree of purification, as well as financial considerations. One of the solusions is high quality equipment, proven in the oil product purification market. One such product is GlobeCore’s UVR-450/16. This system can be successfully used for purification of diesel fuel, as well as gas condensate, gasoline, kerosene etc. The UVR-450/16 can also purity industrial, turbine and other types of oil. By purchasing such equipment you become an owner of a highly productive mini-plant, aimed at a wide spectrum of processes in oil product polishing and regeneration.