In most cases oil storage and heating is accompanied by occurrence of additional moisture. Fuel oil containing water lead to disruption of combustion mode, contamination of heating surfaces, incomplete fuel burning, formations of unburned coke and deposits of particles along the gas passage. Furthermore, the use of such raw materials may cause flameouts and emergency stopping of the equipment.

The best solution, to avoid the negative effects listed above, is a preliminary preparation of fuel oil for combustion. The essence of this approach is to provide a uniformly distributed fine fraction of moisture in fuel oil due to the destruction of quasicrystalline structures.

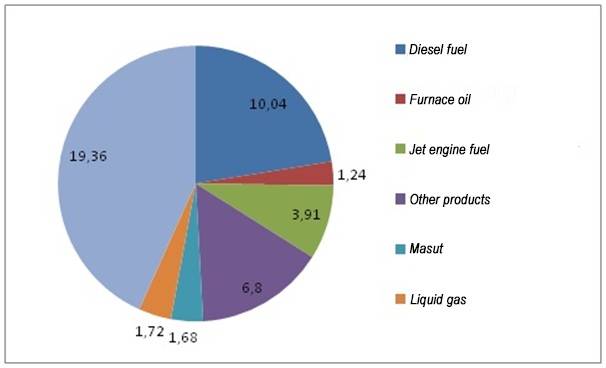

GlobeCore has developed USB plants for the production of water-fuel emulsions (including hydrostabilized fuel oil) from normal and degraded fuel oil, waste oil, diesel and furnace oil, crude oil and oil refinery waste.

Hydrostabilized fuel oil is synthetic fuel consisting of two liquids that are insoluble in each other. It was hypothesized that burning of water-oil emulsion can improve quality parameters of combustion process as well as reduce the amount of toxic emissions. To confirm this hypothesis, it was necessary to solve the following problems:

- to determine technical and economic performance of boiler units M 100 using fuel oil and hydro stabilized fuel;

- to determine the quantity of hydrocarbons, sulfur and nitrogen oxides emissions for each tested fuel type during operation at different loads.

The corresponding experiments were carried out for DE 16-14 GM boiler unit.

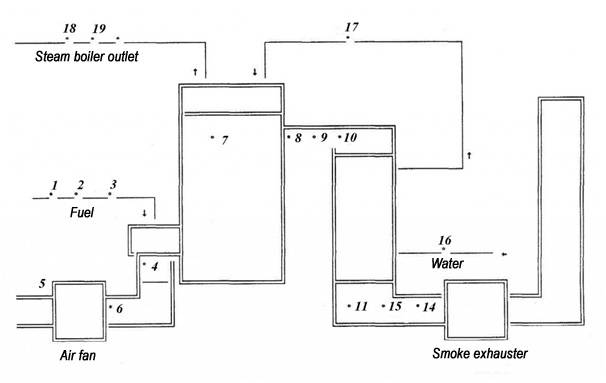

Fig. 1 shows a diagram of measurement points for DE 16-14 GM boiler when using fuel oil.

Fig. 1. DE 16-14 GM boiler measurement points diagram: 1 – fuel pressure in the pipeline, 2 – fuel pressure on the burner, 3 – fuel temperature, 4 – air pressure on the burner 5 – cold air temperature, 6 – air pressure downstream of the fan 7 – combustion chamber rarefaction, 8 – rarefaction downstream of the boiler 9 – flue-gas temperature downstream of the boiler, 10 – flue-gas analysis downstream of the boiler, 11 – rarefaction downstream of the economizer, 14 – outgoing gas temperature, 15 – outgoing gas analysis, 16 – water temperature upstream of the economizer, 17 – water temperature downstream of the economizer, 18 – boiler outlet steam pressure 19 – boiler outlet steam flow

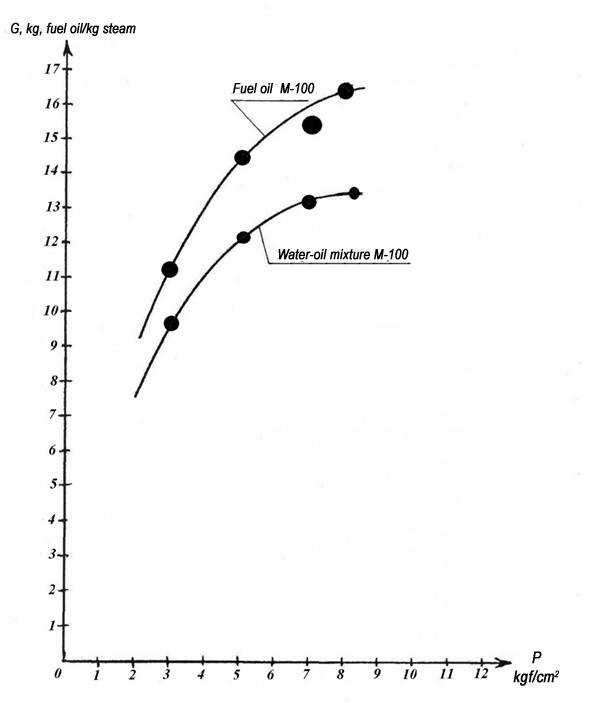

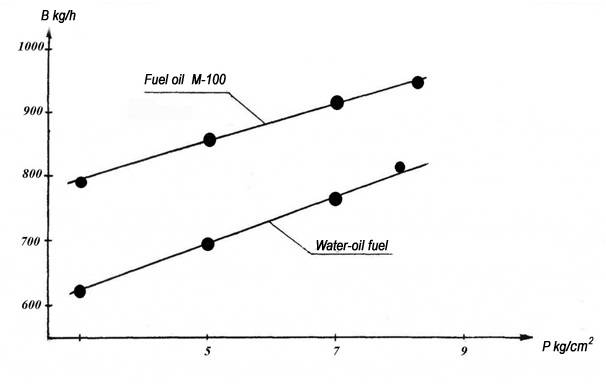

The characteristics obtained as a result of the experiments are presented in the figures below.

Fig. 2. DE 16-14 GM steam boiler flow characteristics when using fuel oil and water-oil mixture: G – Specific steam production, Р – fuel oil pressure (water-oil mixture) upstream of the burner

Fig. 3. Fuel consumption relation to the burner pressure

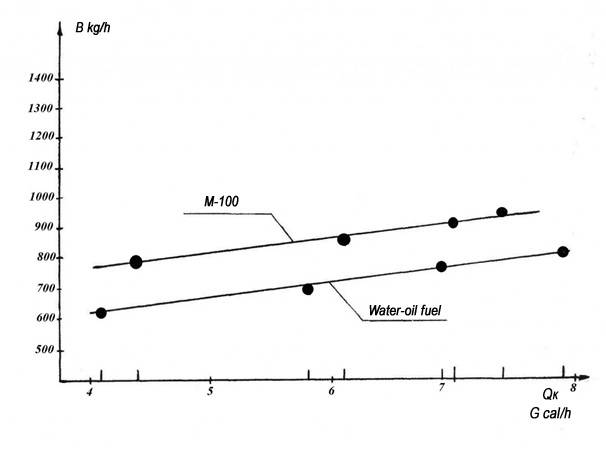

Fig. 4. Fuel consumption relation to the boiler unit load

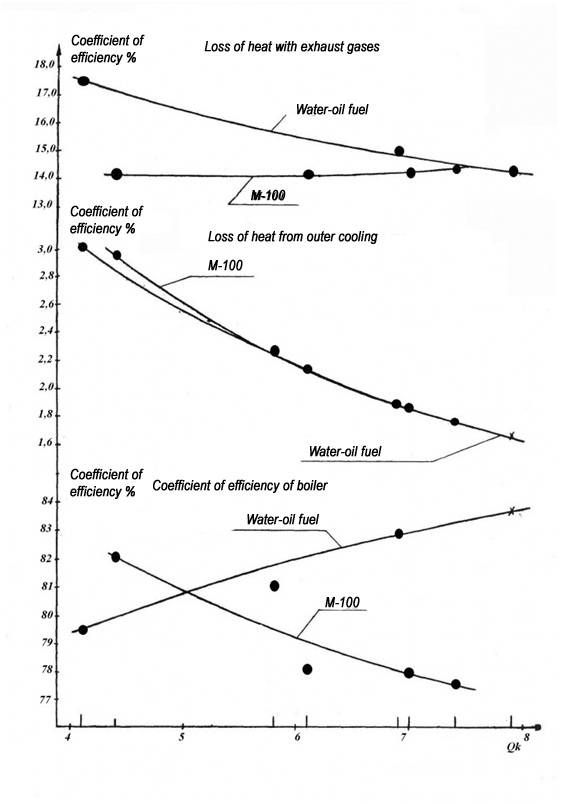

Fig. 5. Heat losses and boiler unit efficiency: Qk – boiler unit heat load

Specific performance of standard and thermally stabilized fuel was also investigated. The results are shown in Table 1.

Table 1

Specific performance of standard and thermally stabilized fuel

| Load, Gcal/h | 4.1 | 4.4 | 5.8 | 6.1 | 6.9 | 7.0 | 7.4 | 7.9 |

| Fuel oil M-100 | 9.59 | 12.18 | 13.11 | 13.38 | ||||

| Hydrostabilized fuel | 11.25 | 14.19 | 15.42 | 16.5 |

After analyzing the data obtained, we can make the following conclusions. The use of hydrostabilized fuel, prepared with the help of GlobeCore USB plants, allows to:

1) increase the economic efficiency of a boiler unit. Hydrostabilized fuel oil is not only as good as conventional furnace fuel oil, but it outperforms it;

2) reduce the amount of pollutants:

- nitrogen dioxide, by 23%;

- sulfur dioxide, by 26%;

- carbon monoxide, by 84%;

- suspended solids, by 87%.

Moreover, the use of hydrostabilized fuel oil, produced with GlobeCore equipment, also allows to receive a number of additional benefits:

- increase the service life of boiler equipment;

- ensure reliable operation of a boiler when original fuel oil is watered;

- exclude settling and draining operations from your fuel preparation technology;

- reduce the intensity of low-temperature sulfuric acid corrosion of your equipment;

- use fuel oil of lower quality in order to generate heat.

USB hydrostabilized fuel oil preparation plants are successfully used by the representatives of heating and power complex – boiler houses, central heating stations, etc.