Fuel economy additives are special substances resembling lube oil. They can be added either directly into a vehicle’s fuel tank or into a fuel storage tank. There is a wide variety of fuel additives in the market.

Depending on their function, the additives may be divided into several types. Antifriction additives, as the name suggests, reduce friction between moving parts of the engine. These additives are effective, but not in terms of fuel savings, which is no more than 5%. Restoration additives restore worn internal surfaces in the engine. Those include small cracks in cylinder walls. This helps engine power and compression. Cleaning additives remove carbon deposits and other combustion products. Those additives are added into the oil when the oil is changed or during fuel filter change. Dehydration additives capture moisture to prevent freezing in cold weather. These protect the engine from premature wear, since even a few drops of water can be detrimental to its function.

Fuel saving additives are probably the most numerous additives in the market. Producers claim fuel savings of 15-20%.

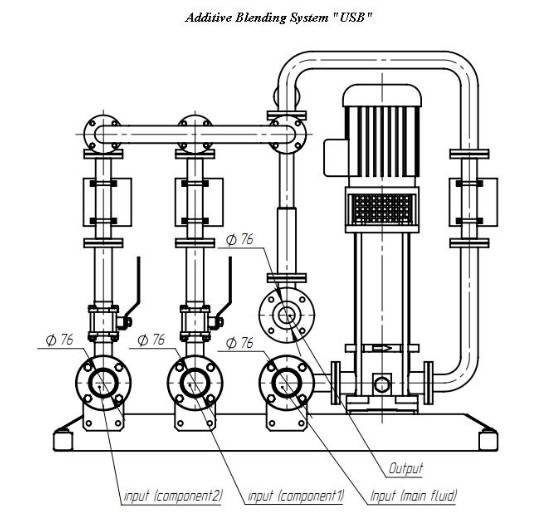

When working with large volumes of fuel, introduction of additives requires special equipment. The thing is that most of the existing mixing methods simply cannot ensure consistent product homogeneity, causing quick separation.

GlobeCore’s USB blending unit are different. The blending system can mix any two to five fluids. Those may be low octane gasoline and additives, for instance. The unit’s main feature is that the use of injection and hydrodynamic shock increases the fuel’s octane (or cetane) number, preventing separation for 180 days.

Using the GlobeCore process improves fuel combustion and improves mileage, increasing engine power and preventing wear of the fuel system components.