A fuel filter consists of a case containing a special filtering element. They are classified depending on their purpose, location, fineness, design, principle of operation and regeneration type.

The main purpose of the filter is to remove solid particles and/or water from oil. In terms of location, filters can be stock, installed and supplied with the engine, or used in the process of fuel preparation. There also filters for bunker fuel facilities.

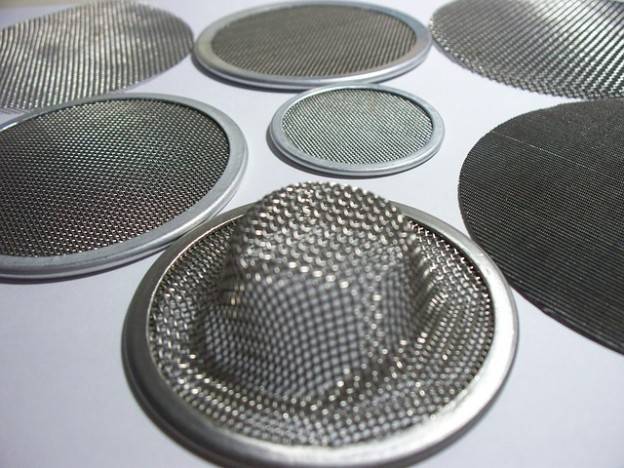

In terms of filter material, there are mesh, fiber, slot, fabric, metal-ceramic, pa,per, plastic and cardboard filters. This list is likely incomplete, since new materials come into use all the time for better purification of oil.

Depending on the way of contaminant capture, there are surface and depth filters.

The former capture contaminants on the surface of the filtering material. Such filters have a large cross section area at fuel inlet. The filtering element is usually cardboard, fabric, paper or similar material.

The latter differ from surface filters by capturing contaminants not only on the surface, but also throughout the volume of the filtering material. They have smaller cross section area, but thicker filtering material (over 20 mm usually). Materials used are thick cardboard, metal-ceramics, felt, fibers or plastic.

The advantage of depth filters is the ability to capture particles of varying size. Devices made of fibrous or granular materials tend to form through channels. Some fuel may pass through them with insufficient purification.

Depending on the number of uses, filter can be single or multiple use. The former operate for a certain amount of time and must then be replaced. The latter can be reused, obviously, after rinsing or some other form of reactivation. The drawbacks of depth filters are the time required for purification, and in some cases impossibility of filter restoration.

In terms of fineness, there are fine and coarse filters.

Fine filters must not let through particles from 1 to 20 micron. This allows for normal operation of engine and fuel system.

Coarse filters are used for removal of 80 – 100 micron particles. Their main task is to guarantee normal operation of a fine filter.

The use of diesel fuel compliant with norms and regulations in terms of solid particles and water content, the stock fuel purification devices of the engine are usually sufficient. However, in some cases fuel quality is an issue and may require additional filters (separators, inline filters) in the fuel preparation system.