Category Archives: Uncategorized

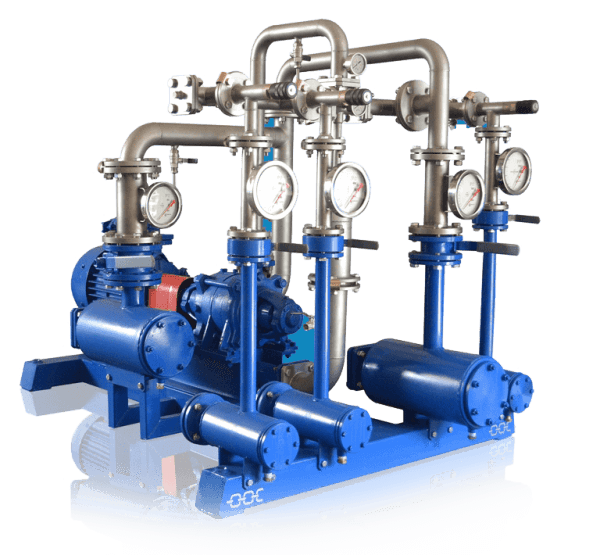

Ethanol & bioethanol blending system USB-60/5

Ethanol blending system

Windshield wash: ingredients define properties

Windshield wash is always in demand, since no vehicle can do without it. Obviously, the better the sales, the more profit for the manufacture. Demand leads to increased prices. The higher the price, the more lucrative the production. Production, however, requires knowledge of the composition.

This information is not secret. Manufacturer are legally required to indicate the composition of their product on the label.

The base component of the windshield washer is alcohol. It assures stability to cold temperature. Most often, washer liquids are based on ethyl, isopropyl or methyl alcohol. The selection is limited by law and the influence of the alhocol on the human body (some substances may be banned for use).

Water is another component. Since the finished product must not contain contaminants or sediment, water should be sufficiently clean. Besides, if the water contains a lot of iron and mineral salts, the performance of the washing fluid suffers. Cloudy solution and sediment are harmful to the spraying nozzles.

Surfactants remove dirt from the glass surface, including wax, soot, dirt and exhaust sediment.

Ethylene glycol is required to keep the liquid flowing, actually preventing freezing of the washing liquid.

For color, dyes are mixed into the liquid. If the color is too dark, it might be because the liquid is low quality and the producer wants to hide cloudiness or sediment.

Odorants are used two attenuate the alcohol odor. Those are non-allergenic and safe. Most drivers and passengers prefer flower and herbal scents.

The soap income – treatment for the liquid soap production

The recently popular liquid soap is in constant demand, with a large market for producers. Liquid soap has less drying effect on the skin, since it contains less alkali. Besides, it does not dry or turn into muck in the soap holder. Besides, the liquid soap is more healthy, not being touched by many people like solid soap is.

Liquid soap is produced by hydrolysis of fatty acid ester with alkali. This process is referred to as saponification. To prepare liquid soap, substitutes are used, such as colophony, tallow fat, fatty acids, nafta acids, or vegetable oil and animal fat.

The actual process used depends on the facility. The soap often contains softening, moisturizing or therapeutic components. Beside the obvious effects the above additives improve the liquid soap compared to regular alkaline soap.

Adding more ingredients into the soap, such as flavors, plant extracts, ester oils, of which many are natural components, increases the demand for the product. Saving on materials may increase the profit in the short run, but will not bring more sales ultimately.

There are several ways of producing liquid soap. Some of them are based in mixing of ingredients. However, there are such processes and melting and chipping, processing of solid soap into liquid using complicated machinery. Besides, solid soap has its own market and users.

The two other ways of making liquid soap – hot and cold – are considered more efficient.

The hot method, as is obvious from its name, involves heating of fats, saponification with alkali and cooling them, Dyes are rarely used with this process to increase product quality.

Making liquid soap using cold method is not only advantageous over teh hot process, but can be done using various blending equipment taken from other industries and improving liquid soap production.

Mixing of liquid soap allows to combine the process of adding dyes and flavors into a single operation.

At this time there is a variety of equipment to make liquid soap, mostly made in China. The process line includes a mixer, a mill, a forming machine, pressing machine, a refrigerator and a cutter, if solid soap is produced.

Therefore, using an all-in-one system for blending of liquid component is more efficient. Investments into new equipment return due to the high production capacity of the equipment, which accelerates production.

High quality product can only be made using good initial materials and efficient machinery. With universal blending systems and high quality ingredients, liquid soap production can be a winning strategy for good profit.

Single technological process of liquid detergents production, is it possible?

Detergents can be solid, liquid, powder (granulated) and paste like. Although powders lead the sales, possessing the highest concentrations, the liquid detergents are also quite popular, not without the help of advertisement.

The production of liquid detergents involves preparation of complex multi-component mixes. These are based on synthetic detergents. They can increase foam and emulsification of the product and reduce water interfacial tension. Such component is usually a surfactant: anionic, amphoteric, cationic and non-ionogenic.

The higher the detergent effect and surfactant biodegradability, the better and more efficient the detergent.

The production of detergents uses such materials as hydroxyolefinsulfonates, fatty acid ester sulfonates, oxyethylated fatty alcohol sulfates. Alkylsulfates is another popular additive due to good detergent action and high degradability.

Specific surfactants exist in the recipes of detergent production as anti-statics, corrosion inhibitors, water repellants, emulsifiers and disinfectants.

The process of liquid detergent production includes several stages, such as, preparation of the mix, drying and packaging. The first stage is the process of mixing surfactant with additives. The resulting solution is uneven and requires processing through a colloid mill.

To avoid breaking the technology process into too many stages and to accelerate the production process, as well as to homogenize the fininshed producti, a modern liquid blending system should be used. This allows to combine several stages of production into one, managed by computer-controlled formulation, precise dosage of the components, continuous mixing and fast production rate.

The obsolete methods of liquid detergent production have significant drawbacks, such as high energy costs, high consumption of materials, negative environmental effects and possible decomposition of sodium tripolyphosphate.

Some elements of the blending equipment: stainless steel mixing chamber, the pump, a separate intermediary vessel, fast replaceable filters and portioning devices are now all included in the new liquid blending unit. Coarse and fine filters, portioners, powerful pumps all increase the general production rate of the liquid detergent; the same equipment can be used for other applications.

The product range of synthetic detergent producer and the company’s ability to develop depend on many parameters. These include the cost of materials and power, changes of modern washing appliances, environmental standards, temperature and mineral content of water, application of the detergent and, of course, on the performance of equipment used to make the detergent.

How to Increase the Cetane Number of Diesel Fuel?

Such additives as nitro compounds or synthins are added to diesel fuel to increase its cetane number. In practical terms, the special equipment in the USB line is used to inject additives and obtain homogenized fuels. They are considered to be an integral part of the production process when increasing the cetane number by a described method.

The combustion of diesel fuels is affected by the design of the equipment and its operational principles. The combustion chamber should be designed in such a way that it will benefit the vortex formation (when the air is compressed) that allows for the reduction of fuel heating. It is desirable to use cast iron pistons, as they have a lower thermal conductivity that reduces the combustion distance (the air and fuel are heated actively).

The fractional composition of fuel is needed while assessing the quality of diesel. This composition may be defined by the flash temperature or in the same way as fuel composition.