Another GlobeCore machine was commissioned on 13-17 January in Guayaquil, Ecuador.

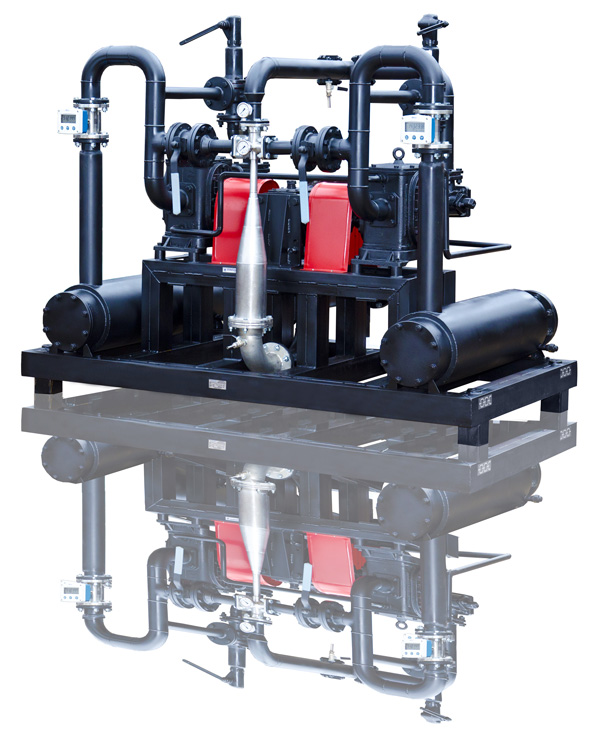

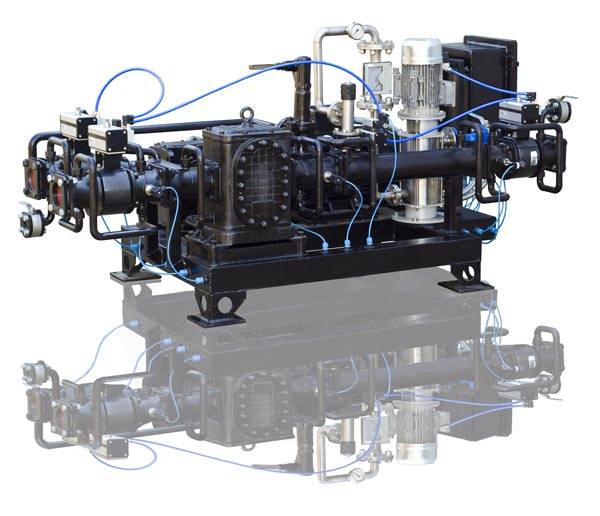

This time our engineers commissioned a 10 cubic meter per hour USB fuel blending machine.

The problem of atmospheric pollution is important for Ecuador, and the government is increasing environmental protection measures and standards. A complete transition to alternative fuels requires a comprehensive upgrade of fuel systems, which does not seem possible at this time. The optimal solution is production of blended fuel using components with a smaller environmental footprint. The USB machine can blend from two to five liquids to make a fuel that can be used in existing engines without modifications and has the same or better performance.

Mr. Wildkad Rodriguez, a representative of the client, made this comment on the commissioning, “After the environmental standards had been increased, we ran into problems with sulfur dioxide SO2 emissions. We now use the USB to make fuel from two ingredients. The other component is not only more environmentally friendly, but is also less expensive. We now achieve several objectives at once: maintain efficiency, reduce emissions and decrease costs. The USB is an outstanding machine. It meets our requirements quite well”.